- More than 2 years ago

A team of environmental engineers at Pennsylvania State University has created a fuel cell that breaks down organic matter in wastewater and, in the process, generates small amounts of electricity.

The researchers say this dual activity could significantly reduce the costs associated with current water treatment in industrialized countries and make such treatment more widely available in developing countries.

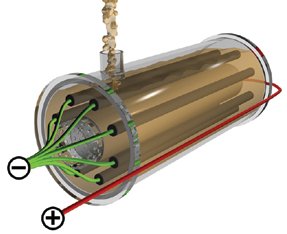

The prototype fuel cell consists of a cylindrical Plexiglas chamber, 15 centimeters long and 6.5 cm wide, in which the researchers arranged eight graphite rods around a hollow carbon-and-platinum tube. The rods serve as negative electrodes, or anodes, and the tube serves as a positive electrode, or cathode.

When the researchers pump a sample of wastewater from the local treatment plant into the fuel cell, bacteria in the water stick to the graphite rods.

There, the microbes break down the sample’s organic matter in a process that extracts electrons from the waste and transfers them to the rods. From there, the electrons flow through a wire to the cathode, generating electricity.

The breakdown of the organic matter also generates protons, which migrate through the wastewater toward the cathode. There, the protons combine with electrons and oxygen to form pure water.

Researchers have already fabricated microbial fuel cells that run on glucose (SN: 10/25/03, p. 270: Available to subscribers at Sweet-toothed microbe tapped for power). However, says lead investigator Bruce Logan of Penn State in University Park, “I don’t think anybody believed that you could do this with domestic wastewater.”

“It’s a completely new concept for treating wastewater,” concurs Bruce Rittmann, an environmental engineer at Northwestern University in Evanston, Ill.

Current treatment facilities use bacteria-laden tanks to clean wastewater. To do their job, the bacteria require oxygen, which accepts electrons from the waste.

Half of the $25 billion spent annually on wastewater treatment in the United States goes to aerating tanks, according to the Association of Metropolitan Sewerage Agencies.

The fuel cell–based wastewater-treatment system could eliminate this costly requirement, Logan says. What’s more, the electricity the fuel cell generates could be used to pump water through the system.

So far, the fuel cell can produce up to 150 milliwatts of electricity per square meter of electrode surface. With improvements to the system, “I think we can probably reach something on the order of 500 to 1,000 milliwatts per square meter,” says Logan. This would be enough power to pump an entire community’s waste.

He and his colleagues describe their new fuel cell in an upcoming issue of Environmental Science & Technology.

Currently, the bacteria in the Penn State fuel cell can eliminate close to 80 percent of the organic matter in wastewater, a performance approaching that of existing treatment methods. By covering the electrodes with specific strains of bacteria that are especially adept at breaking down waste, the researchers could make such devices even more efficient, Rittmann says.

The fuel cell also needs to become less expensive, says Logan. He and his colleagues are exploring different materials that would reduce the costs of its components.