How seafood shells could help solve the plastic waste problem

Chemists are finding better ways to extract biodegradable materials from crustaceans and insects

SHELL GAME Langoustine (Nephrops norvegicus) claws are a rich source of chitin and chitosan, biodegradable materials with possible applications in eco-friendly food packaging and beyond.

Urbanbuzz/Shutterstock

Lobster bisque and shrimp cocktail make for scrumptious meals, but at a price. The food industry generates 6 million to 8 million metric tons of crab, shrimp and lobster shell waste every year. Depending on the country, those claws and legs largely get dumped back into the ocean or into landfills.

In many of those same landfills, plastic trash relentlessly accumulates. Humans have produced over 8 billion tons of plastic since mass production began in the 1950s. Only 10 percent of plastic packaging gets recycled successfully. Most of the rest sits in landfills for a very long time (a plastic bottle takes about 450 years to break down), or escapes into the environment, perhaps sickening seabirds that swallow tiny pieces or gathering in the Pacific Ocean’s floating garbage patch (SN Online: 3/22/18).

Some scientists think it’s possible to tackle the two problems at once. Crustaceans’ hardy shells contain chitin, a material that, along with its derivative chitosan, offers many of plastic’s desirable properties and takes only weeks or months to biodegrade, rather than centuries.

The challenge is getting enough pure chitin and chitosan from the shells to make bio-based “plastic” in cost-effective ways. “There’s no blueprint or operating manual for what we’re doing,” says John Keyes, CEO of Mari Signum, a start-up company based just outside of Richmond, Va., that is devising ways to make environmentally friendly chitin. But a flurry of advances in green chemistry is providing some guideposts.

Nature’s scaffold

Chitin is one of the most abundant organic materials in the world, after cellulose, which gives woody plants their structure. In addition to crustaceans, chitin is found in insects, fish scales, mollusks and fungi. Like plastic, chitin is a polymer, a molecular chain made from repeating units. The building block in chitin, N-acetyl-D-glucosamine, is a sugar related to glucose. Chitin and chitosan are antibacterial, nontoxic and used in cosmetics, wound dressings and pool-water treatments, among other applications.

Getting the chitosan requires an extra step: adding hot, concentrated sodium hydroxide solution to the chitin. To do this work in a sustainable way, companies must invest in pricey corrosion-resistant reactors, wastewater treatment and carbon dioxide capture technology.

The harsh reactions used today also sever the long polymer chains that make the materials sturdy, limiting chitin’s and chitosan’s versatility. Mari Signum’s chief technology officer, Julia Shamshina, offers a clothing analogy: It’s impossible to make a sweater with a ball of yarn made only of short threads.

Seafood suppliers face economic drawbacks as well. Today, U.S. producers pay landfills to take their shells. But those who want to keep the waste out of the landfill and support chitin production must still pay to dry the shells and transport them to often faraway extraction facilities, like Mari Signum. For its part, Mari Signum is changing the equation by paying the transportation bills for its Gulf Coast suppliers. Once Mari Signum is profitable, the company says it will also pay those suppliers for their shells.

When Keyes was a pro bono consultant for an aquaculture business a few years ago, he faced that same food waste decision. The company planned to haul its shells to regional landfills, Keyes says, “until we … tracked down Robin Rogers.”

Get it separated

If the slight drawl doesn’t give Rogers away as a native Alabaman, his ever-present blazer in Crimson Tide red does the trick. A University of Alabama chemist and a cofounder and co-owner of Mari Signum, Rogers started tackling shell waste in 2010, when the Deepwater Horizon oil spill devastated Gulf Coast shrimpers. Mari Signum licensed his technology in 2016. “We found we could take shrimp shell, dissolve the chitin directly and pull it away from everything else,” Rogers says.

The key was to find a liquid that could dissolve chitin, because water cannot. Thousands of repeating sugar units in chitin entangle themselves via countless interactions known as hydrogen bonds, and neither water nor most organic solvents can penetrate that network. Rogers solved that problem by dissolving shell waste in an ionic liquid.

Ionic liquids differ chemically from water and organic solvents. The chemical bonds in a molecule of water — H2O — are covalent: They involve shared electrons. Ionic liquids, in contrast, feature an ionic bond like that seen in table salt, sodium chloride, in which no electrons are shared but the attraction between a positively charged ion, called a cation, and negatively charged ion, or anion, holds things together. While ionic liquids may be saltlike, they are not exactly like table salt. Transforming solid table salt crystals to a liquid requires a temperature about 1.5 times as hot as the surface of Venus, but an ionic liquid can be liquid at room temperature.

Their chemical makeup helps ionic liquids dissolve chitin where other solvents fail. To dissolve chitin in shrimp shells, Mari Signum uses 1-ethyl-3-methylimidazolium acetate. This ionic liquid belongs to the lowest chemical toxicity category, according to United Nations standards. “I tell people half of the ionic liquid we’re using is vinegar,” Rogers says, because negatively charged acetate is present in everyday table vinegar, which is a dilute solution of acetic acid in water. Acetate is a small molecule, in addition to being charged, so it infiltrates chitin’s hydrogen bond networks. Microwave heating activates the hydrogen bonds to enable separation without cutting the polymer chains.

Mari Signum’s process requires neither hydrochloric acid nor sodium hydroxide, and the ionic liquid can be used again and again. The shells’ calcium carbonate is a waste by-product, but the company is looking into providing that waste to makers of paint additives or heartburn medication, where this compound is already used commercially.

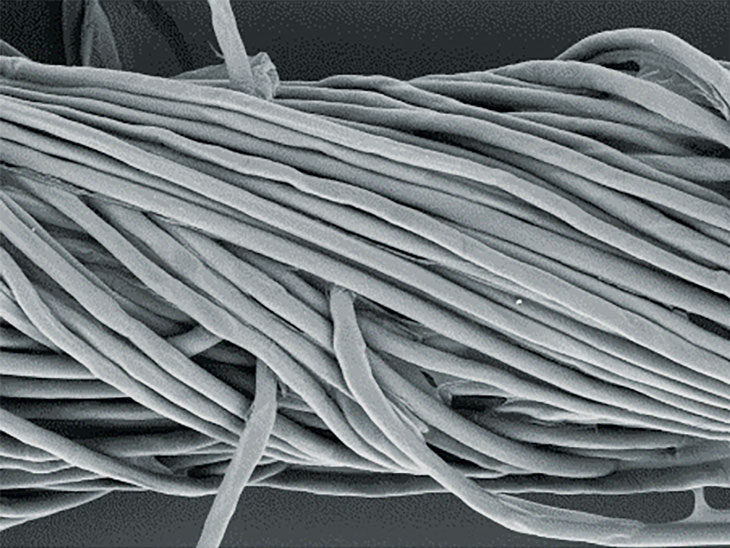

Shamshina, Rogers and chemist Paula Berton of the University of Calgary in Canada showed that their chitin, extracted by ionic liquid, can be converted to fibers and hydrogels — materials that can absorb and retain water. In the April 1 ACS Sustainable Chemistry and Engineering, the researchers described potential uses in wound-care materials and biodegradable delivery vehicles for drugs. Plus the group produced novel materials, such as chitin microbeads that could be a biodegradable substitute for the banned plastic microbeads that were used in cosmetics (SN Online: 1/4/19).

Ionic liquids aren’t the only chemistry solution to the chitin extraction problem. Chemist Audrey Moores’ team at McGill University in Montreal published a patent-pending approach to minimizing use of water, or any liquid, online on March 26 in Green Chemistry. Moores’ research assistant Thomas Di Nardo takes shell powder from crustaceans or insects and pounds it with a ceramic ball inside a mechanical mill. This step loosens the hydrogen bonds between chitin’s many chains. Scientists call this approach mechanochemistry.

“Instead of giving energy to your reaction in the form of heating, you’re giving it in the form of mechanical force,” Moores says. Next, instead of employing sodium hydroxide dissolved in water, Di Nardo adds solid sodium hydroxide to the mill, mixes for a few minutes and then transfers the mixture to a steam room–like chamber, where it ages for six days. Each of chitin’s many N-acetyl-D-glucosamine building blocks contains a chemical group that’s akin to a gloved hand. During aging, the sodium hydroxide removes most of the gloves, yielding chitosan.

Compared with the traditional conversion of chitin to chitosan, Moores estimates that the process uses only about a third to a fifth as much energy, an eighth as much sodium hydroxide and a tenth as much water. The process also produces very long polymer chains.

One drawback: Only 10 grams can be made at a time. But Moores received funding from McGill this spring to find ways to produce greater quantities. The next goal is 10 kilograms, and preliminary talks with collaborators suggest it’s doable. Moores is also working with an expert on green plasticizers, to convert her sturdy chitosan into something moldable like the plastics in single-use packaging. A company that makes antibacterial clothing fibers has reached out to her as well, about potentially using her chitosan, which is naturally antibacterial, for the fibers. In May, Moores and Di Nardo launched a spin-off corporation, ChitoDry.

Unsustainable

The traditional way of procuring chitin and chitosan is wasteful and leads to inconsistent product quality. Researchers are working on improvements.

| Process | Drawbacks | |

|---|---|---|

| Remove shells from seafood | ||

| ↓ | ||

| Dry/crush shells into powder, usually near fishing location | ||

| ↓ | ||

| Send powder to facility for chitin purification |

|

|

| ↓ | ||

| Remove minerals with hydrochloric acid in water |

|

|

| ↓ | ||

| Remove proteins with hot sodium hydroxide in water |

|

|

| ↓ | ||

| Remove wastewater |

|

|

| ↓ | ||

| Chitin | ||

| ↓ | ||

| Add hot, highly concentrated sodium hydroxide in water |

|

|

| ↓ | ||

| Remove wastewater |

|

|

| ↓ | ||

| Chitosan |

Put bacteria to work

What if chitin could be extracted without adding any lab-made chemicals? Because chitin and chitosan can be made from living things, a biological extraction seems like a reasonable approach to chemist Cait Murray-Green. At CuanTec in Scotland, where she is CEO, microbes obtain chitin and chitosan from the shells of langoustines, crustaceans common to Europe’s northern seas.

CuanTec’s process takes advantage of clever microbial chemistry. “Our bacteria produce natural acids, which are a direct replacement for harsh hydrochloric acid,” Murray-Green says. The team has also eliminated about 95 percent of the sodium hydroxide the traditional process requires and cut energy use by two-thirds, she adds. The process yields long, robust polymer chains.

The company’s first product will be compostable, antimicrobial food packaging. Recent tests suggest that the packaging extends fresh salmon’s shelf life by three days over traditional plastic. In April, CuanTec announced a partnership with British supermarket chain Waitrose & Partners to produce flexible film packaging for fish. Waitrose hopes the film will be available in 12 to 18 months. “This story is about using food waste to prevent food waste,” Murray-Green says.

Only certain bacteria are suitable for purifying chitin from food waste. CuanTec’s microbial cocktail is proprietary, but at the Fraunhofer Institute for Interfacial Engineering and Biotechnology in Stuttgart, Germany, Susanne Zibek’s team selects microbes that consume the shells’ protein but not the chitin.

Those same microbes secrete lactic acid, which substitutes for hydrochloric acid. Zibek leads ChitoTex, an international chitin research consortium. Among her collaborators is Protix, a Netherlands firm that produces larvae from the black soldier fly as a protein source for animal feed. The company sought to make use of chitin-rich insect skins and Zibek thought of an alternative to nonrenewable substances in the textile industry.

During the weaving process, yarn experiences mechanical stress. To prevent breakage, manufacturers add a temporary plastic coating, which they wash away prior to dyeing. Companies frequently use polyvinyl alcohol for the coating, which comes from fossil fuel sources. Zibek’s team has developed an alternative using the Protix waste: a temporary chitosan coating for yarn. The most she can make in one batch is 500 grams, too small to meet a textile company’s needs. Before the technology can be viable, she has to find a way to produce more material and to recycle the water required for the process.

Green ambitions

Chitin and chitosan alone will never replace all of the world’s plastic, which has an enormous range of properties. Plastics production is increasing, and even if all 6 million to 8 million tons of the world’s yearly shell waste could be processed for chitin, the material would be a tiny fraction of the 311 million tons of plastic that humans produced in 2014.

Farming more shrimp would boost the amount of available chitin somewhat. Mari Signum’s sister company, Global Blue Technologies, based in Rockport, Texas, is developing indoor aquaculture ponds that will not discharge any waste to the environment, thanks to proprietary filtration technology. Hurricane Harvey destroyed the facility in 2017, but when it’s rebuilt, Mari Signum will be able to get shrimp shells from five to 10 molts as the shrimp grow, instead of the single shell available from fisheries.

For now, Keyes is sharing his vision with potential partner companies. He hopes to encourage a new ecosystem of businesses to operate in the Richmond area, which happens to be close to the Chesapeake Bay, famous for its crabs, as well as the port of Norfolk, which could in theory receive shipments of shell biomass from elsewhere.

Keyes likens the area to Silicon Valley, which was once primarily an agricultural region. “Then they developed this little thing called a microchip,” he says, and an entire economic engine sprang to life.

The Richmond region’s microchip could be high-quality chitin, Keyes contends. “It’s this miracle of nature,” he says. “Right now, it’s basically being thrown away.” But the right chemistry could keep both shells and plastic out of landfills.

This story appears in the June 22, 2019 Science News with the headline, “Shell Game: Transforming biodegradable seafood waste to cut down on plastic.”