A new twist on a twist

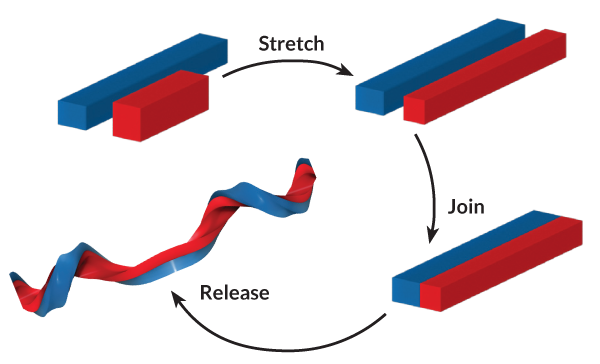

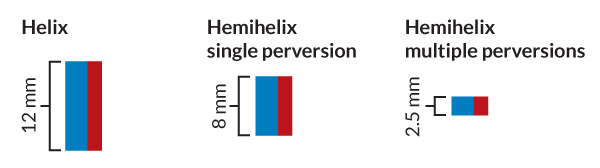

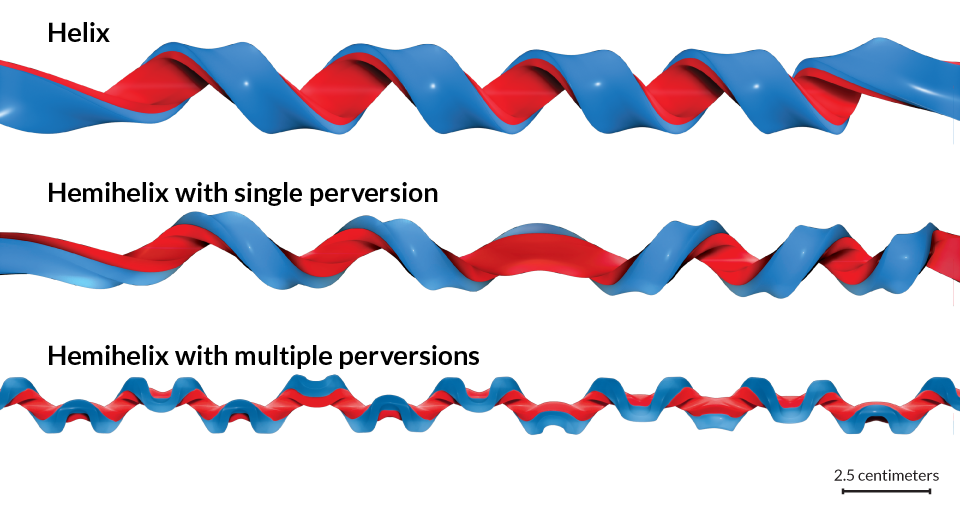

TWISTED Nature's famous helix formation, which forms the shape of DNA, ram's horns and seashells, can be tuned to make hemihelices — reverse windings of the original structure. Perversions are the changes in direction in a hemihelix.

Maluchi Enyi