- More than 2 years ago

Through engineers’ never-ending quest for miniaturization, computers and other electronics keep getting smaller. But for many components, the rules change when their size approaches the nanoscale–where parts are just billionths of a meter across. Laws that rule in a gallon or a gram of material no longer apply. That’s the dilemma for the makers of materials such as the iron oxide–coated disks in computer hard drives. These magnetic devices now store 30 million times as many bits of information per square inch as they did when introduced in 1956.

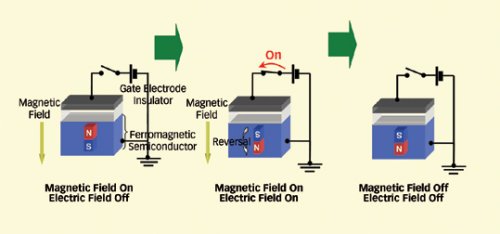

ELECTRIC ASSIST. In this schematic of a nanoscale piece of a hard drive, an applied magnetic field alone can’t rewrite a bit of information. In the left image, the magnetic field within the semiconducting material remains north (N) up and south (S) down. But when an electric field (represented by top switch) supplements the magnetic field (center image), the bit changes magnetic direction. In the right image, with both magnetic and electric fields off, the bit holds its magnetic direction. |

The most sophisticated magnetic recording devices have since gone from storing 2,000 bits of information per square inch to 60 gigabits per square inch, says Mark Kryder of Scotts Valley, Calif.,–based Seagate Technology, which manufactures hard disks and other storage devices. The question now is how long the pace of change can continue.

In particular, engineers face one looming obstacle: Once data storage increases to a certain density, ambient temperature can erase the information recorded on magnetic material. That’s because data are stored by magnetizing tiny regions of the recording medium. The smaller the region, the less magnetic energy it contains, and the thermal energy at even room temperature can overwhelm the magnetism of a small region. When this happens, these regions “lose their magnetic memory,” says Josep Nogués of the Catalan Institution for Research and Advanced Studies in Barcelona.

Researchers need to come up with creative ways around this problem, which they call the superparamagnetic limit. In the near term, Kryder doesn’t sound too worried. Companies that make these magnetic materials have developed or are pursuing promising new ways to keep the superparamagnetic limit at bay for at least several years. But what about after that?

“At some limit, you hit that wall,” says Ivan K. Schuller of the University of California, San Diego.

Fortunately for everyone who wants faster and smarter computers, scientists are working on solutions. In recent tests, they’ve examined ways to reduce temperature effects on magnetic materials and gained insights into designing nanoscale data-storage materials that could be much more thermally stable than is now possible. They’ve also looked into ways to write and rewrite information to dense, thermally stable materials–a major challenge because of the large magnetic fields currently required.

This sort of basic research into magnetic materials may not show up in next year’s personal computers, but according to scientists, it’s the sort of fundamental work that could yield ideas that will govern your hard drive a decade from now.

Short-term memory

Information on hard drives or other magnetic media is stored in the form of bits representing 0s and 1s. An electromagnet records bits by magnetizing small areas of the crystalline film covering the disk. Essentially, each region is a tiny magnet with the north pole pointing either left or right, say, for a 0 or a 1.

As they make bits smaller to increase data density, engineers could make them more stable against temperature fluctuations by using materials that they can magnetize more intensely, notes Hideo Ohno of Tohoku University in Japan. But then it becomes more difficult to rewrite the bits, he says, because a stronger magnetic field is needed to change their orientation.

In the near term, data-storage density will continue to shrink, despite the impending superparamagnetic limit. To push that evolution as far as possible, Seagate, for one, has set out a road map for improving data density over the next decade.

Although commercial materials today have data-storage densities up to 60 gigabits per square inch, the company has demonstrated 100 gigabits per square inch in its lab, says Kryder. That’s using so-called longitudinal recording, the conventional technology, in which the magnetic orientations of bits lie in the plane of the disk.

As early as 2004, the company plans to roll out materials that use perpendicular recording, which magnetizes the film up and down rather than side to side. Because perpendicular bits pack together more tightly than do longitudinal bits of the same size, this technique should produce denser storage without sacrificing thermal stability, says Kryder. Within 6 years, he suggests, data density may increase to 1 terabit per square inch, which is 16 times what it is today.

But even perpendicular recording will stave off the superparamagnetic limit only for a few years. At that point, researchers will again confront the need for new technology to increase storage density, and Seagate plans to turn to a technique called heat-assisted magnetic recording. In this approach, researchers use a laser to heat the exact spot where the magnetic field is applied while writing a 0 or 1.

This could enable researchers to work with materials that can support stronger magnetic fields than are now feasible and thus have higher magnetic energies. With current technology, rewriting bits on these materials requires an impractically large magnetic field. Laser heating, in effect, weakens the magnetization so that researchers can write and rewrite on these materials using a smaller magnetic field. On removal of the laser heat, the material cools and is once again resistant to rewriting, so temperature fluctuations won’t accidentally rewrite the bits. Researchers have already demonstrated heat-assisted recording’s potential in the lab, says Kryder, although the technology isn’t yet ready for the marketplace. He suspects that heat-assisted recording could carry magnetic materials to about 10 terabits per square inch.

Ohno is looking at an alternative to heat-assisted magnetic recording to get around what he says is the difficulty of localizing heat to sufficiently small areas. In experiments on manganese-doped indium arsenide–a magnetic semiconductor–Ohno and his coworkers apply an electric field to assist the magnetic field that’s writing the 0 or 1. By doing so, the researchers report in the August 15 issue of Science, they can reduce the size of the magnetic field needed to rewrite a 0 or 1 on this magnetic semiconductor by 80 percent.

For now, Ohno says, “this is an experimental proof that there are means other than just heating the magnet to make them easier to . . . reverse magnetization direction, which may one day be useful for high-density magnetic-storage applications.” The manganese-doped indium arsenide may not be the material that people use, he notes, because his experiments work only at temperatures below –223C. Nonetheless, says Ohno, researchers may now find other materials or methods for using electric fields to rewrite bits at higher temperatures.

Island dreams

Magnetic media for data storage currently take the form of continuous films, but some researchers see advantages in making computer disks crammed instead with densely packed but magnetically isolated nanoparticles. Although this technology hasn’t yet been demonstrated, Kryder speculates that these tightly packed islands could achieve data densities of 40 to 50 terabits per square inch. Nanoscale islands would still face problems because each one would have little magnetic energy and thus could be easily disturbed by the thermal energy at room temperature.

Nogués and his colleagues decided to see whether they could increase the thermal stability of nanoscale particles by constructing them on a special matrix. The researchers deposited 3-to-4-nanometer-wide cobalt particles onto a matrix of cobalt oxide. The latter is an antiferromagnetic material, meaning that neighboring atoms tend to align their magnetic orientations in opposite directions. In contrast, cobalt itself, like magnetic materials used to record data, is ferromagnetic, meaning that its atoms line up their magnetic orientations in the same direction.

Two years ago, Schuller and his colleagues suggested that antiferromagnetic materials might help stabilize nanoscale magnetic islands. In the June 19 Nature, Nogués’ team reported that this is indeed the case. In the researchers’ experiments, cobalt nanoparticles anchored in a ferromagnetic matrix held their magnetic information up to 17C–nearly room temperature–while those in an ordinary, nonmagnetic matrix lost their orientations above the chilly temperature of –263C. According to Nogués, the antiferromagnetic matrix increases the island’s magnetic energy, so it can withstand more heat than if it were in another type of material.

The antiferromagnetic material in Nogués’ experiment, cobalt oxide, is easy to study in the lab but wouldn’t be useful for industrial applications since it loses its antiferromagnetic properties above 17C, Nogués notes. He and his colleagues are now collaborating with Seagate scientists to identify other materials that retain their antiferromagnetism up to higher temperatures.

There’s still a long way to go before nanoscale magnetic islands find their way into computers or other products, says Schuller. Numerous challenges remain. For example, companies will need a fast and cheap way to make the islands, he says.

Nonetheless, islands have become the focus of intense study. “A lot of people are quite interested in this research and how the properties of the nanoparticles are connected to their shape or size,” notes Wolfgang Kuch of the Max Planck Institute for Mikrostrukturphysik in Halle, Germany.

In the August 2003 Nature Materials, for example, Harald Brune and his colleagues at the École Polytechnique Fédérale de Lausanne in Switzerland report different characteristics for interior and perimeter atoms in a single nanoscale magnetic island. Specifically, they studied the energy required to reverse the direction of an island’s magnetization–a quantity that scientists technically call magnetic anisotropy energy. Brune and his coworkers deposited atoms of cobalt on a platinum surface, forming islands of various sizes. When they analyzed the contribution of the individual atoms to the magnetic anisotropy energy, the researchers found that the perimeter atoms have the largest influence on the phenomenon. Therefore, an island’s magnetic anisotropy energy isn’t proportional to the area of the island, says Brune, but rather to the number of atoms around its rim.

To check these findings, he and his colleagues also made nanoscale islands with a perimeter of cobalt atoms surrounding a platinum interior. These islands, the researchers report, had the same magnetic anisotropy as did islands made entirely of cobalt, as long as both had the same number of perimeter atoms.

Kuch comments that work by Brune and his colleagues suggests a way to tailor the magnetic anisotropy and other properties of magnetic materials very precisely. By placing certain atoms at an island’s perimeter and others in its interior, engineers could make islands that behave exactly as they want.

However, Brune’s research is still very fundamental, Kuch cautions, and the materials used by the team aren’t commercially useful since the team performed their measurements at the uncomfortably cold temperature of –223C.

Moreover, “one never knows what will happen in the future, and maybe some completely different technology will take over before magnetic-data storage comes to the point where one nanoparticle is one single bit,” says Kuch.

Yet down the road, the basic research coming out of academic research centers could help computer-disk makers reach the 40-to-50-terabit goal that Kryder proposes. Such fundamental research is important because, Schuller says, “this produces the ideas that will lead to the useful things.”

Publicly reported university research in this field is rarely ready for prime time, Schuller adds, while companies that have a new data-storage material will put it in a computer before anyone knows about it. He says, “Before you read about it in some science journal, you’re going to buy it.”

****************

If you have a comment on this article that you would like considered for publication in Science News, send it to editors@sciencenews.org. Please include your name and location.